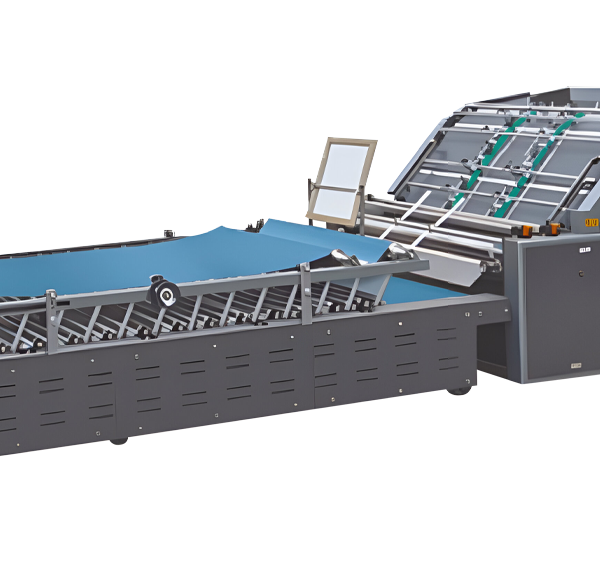

5 Ply Automatic Board Making Plant

The 1600mm five-layer corrugated paperboard production line offers a maximum width of 1600mm, with an optimal speed of 60-80m/min. It supports A, C, B, and E flute combinations, and operates on a 380V, 50Hz power supply, consuming about 80 Kw at full speed. The machine requires 2500-3000 Kg/Hr of electricity, with pressures up to 1.2 MPa, and occupies approximately 60m x 10m x 5m. It is compatible with various paper grades, including domestic and imported options.

Capability and Features

Main Technical Parameters and requirements in production line

1. Production Specifications

- Maximum Production Width: The corrugated cardboard produced can be up to 1600 mm wide, accommodating a variety of large-scale packaging needs.

- Design Speed: The machine is designed to operate at a maximum speed of 100 meters per minute, ensuring high productivity for large orders.

- Economic Speed: For optimal efficiency and cost-effectiveness, the recommended operating speed ranges from 60 to 80 meters per minute. This range balances production speed with energy consumption and machine wear.

Note: For accurate speed testing and optimal operation, the paper used in production must meet the following conditions:

- Surface Temperature: The equipment should maintain a surface temperature of at least 172°C.

- Top Paper: Weight should be between 100 and 250 g/m².

- Core Paper: Weight should be between 100 and 250 g/m².

- Paper Quality: Should be at least B grade.

- Paper Moisture Content: Should be around 11%, with a tolerance of ±2%.

- Corrugated Paper: Weight should be between 100 and 200 g/m².

Flute-Type Combination

- The production line supports various flute-type combinations, including A, C, B, and E flutes. This flexibility allows manufacturers to produce a range of corrugated board types to meet different strength and cushioning requirements based on customer specifications.

2. Electricity Requirements

- Electric Consumption: The equipment consumes between 2500 and 3000 Kg/Hr of electricity, depending on the operational load.

- Pressure Requirements:

- Highest Pressure: 1.2 MPa, ensuring robust and stable operation under peak conditions. Common Pressure: 0.8-1.1 MPa, typically maintained during regular operation to ensure efficiency and safety.

3. Power Supply

- The production line operates on a three-phase four-wire system with a voltage of 380V and a frequency of 50Hz, which is standard for industrial equipment.

4. Power Consumption

- Total Installed Power: Approximately 150 Kw, representing the maximum power capacity of all components when running at full load.

- Actual Power Consumption: Around 80 Kw when operating at full speed, reflecting the energy efficiency of the machine during normal production.

5. Equipment Dimensions

- The production line requires significant space, with dimensions of approximately 60 meters in length, 10 meters in width, and 5 meters in height. The specific foundation length may vary based on the installation setup and site requirements.

6. Paper Output Direction

- The direction in which the finished corrugated paperboard is output can be configured to the left or right, based on the user’s plant layout and operational flow requirements. This customization ensures seamless integration into existing production lines.

7. Equipment Applicability

- The production line is compatible with a wide range of paper grades, including A, B, and C class domestic or imported paper. This versatility allows manufacturers to source raw materials based on availability and cost, while still achieving high-quality output.

Customer-Owned Section: Requirements and Responsibilities

To ensure the successful installation and operation of the 1600mm five-layer corrugated paperboard production line, customers are responsible for providing and preparing several essential components and services:

1. Electric Heating System

- Electric Boiler: The customer should supply an electric boiler with a capacity of 4000 Kg/Hr and a pressure rating of 1.25 MPa. This boiler will be crucial for the heating system.

- Electric Pipeline: The necessary electric pipeline infrastructure to connect and operate the boiler should also be provided.

2. Air Systems

- Air Compressor Machine: A reliable air compressor is required to supply compressed air for various pneumatic operations within the production line.

- Air Pipeline: The customer should install air pipelines to distribute compressed air to different sections of the production line.

- Glue Conveying Pipe: Pipelines for conveying glue need to be installed, ensuring efficient and uninterrupted glue supply to the machine.

3. Power Supply

- Electrical Connections: The power supply should be connected to the operation panel, including all necessary wires and line pipes.

- Power Infrastructure: Adequate power infrastructure should be in place to support the operational requirements of the production line.

4. Water Systems

- Water Sources: Reliable water sources are required for various processes within the production line.

- Water Pipelines: Installation of water pipelines to distribute water to necessary sections of the production line.

- Buckets and Containers: Appropriate buckets and containers for water storage and handling should be provided.

5. Civil Foundation

- Mounting Foundation: A solid and well-prepared civil foundation is essential for mounting and stabilizing the production line equipment.

- Water and Electricity Infrastructure: Ensure that the foundation includes provisions for water and electricity supply, facilitating seamless integration of the production line. Lubrication and Oil Equipment

- Oil Equipment: All necessary equipment for oil supply should be provided.

- Lubricating Oil and Grease: Ensure a sufficient supply of lubricating oil, hydraulic oil, and lubricating grease for maintaining the machinery. Installation and Commissioning Support

- Food and Accommodation: The customer is responsible for providing food and accommodation for the installation team during the setup and commissioning phases.

- Installation Assistance: Support the installation team by providing necessary facilities and assistance to ensure a smooth and efficient installation process.

| NO. | EQUIPMENT NAME | QTY | REMARK |

| 1 | SHAFTLESS MILL ROLL STAND | 5 | EXPAND CHUCK,MANUAL DICS BRAKES,

MECHANICALLY - ACTUATED LIFT, PANNING LEFT AND RIGHT ON THE MIDDLE |

| 2 | PAPER TROLLEY | 10 | TRACK LENGTH 4500MM,TROLLEY USED 10MM MEDIUM PLATE WELDING。 |

|

3 |

TOP PAPER PREHEATER |

2 |

ROLLER ¢ 600MM , INCLUDING PRESSURE

CONTAINER CERTIFICATE.ELECTRIC ADJUSTMENT WRAP ANGLE。WRAP ANGLE CAN ADJUST THE PAPER PREHEAT AREA IN THE RANGE OF 360°. |

|

4 |

CORE PAPER PREHEATER |

2 |

ROLLER ¢ 600MM , INCLUDING PRESSURE

CONTAINER CERTIFICATE.ELECTRIC ADJUSTMENT WRAP ANGLE。WRAP ANGLE CAN ADJUST THE PAPER PREHEAT AREA IN THE RANGE OF 360°. |

|

5 |

CORRUGATED SINGLE FACER |

2 |

CORRUGATED MAIN ROLLER ¢ 280MM ,

MATERIAL WITH 48CRMO ALLOY STEEL,INDEPENDENT GEARBOX,UNIVERSAL JOINT TRANSMISSION STRUCTURE。 |

| 6 | TRIPLE PREHEATER |

1 |

ROLLER ¢ 600MM , INCLUDING PRESSURE

CONTAINER CERTIFICATE.ELECTRIC ADJUSTMENT WRAP ANGLE。WRAP ANGLE CAN ADJUST THE PAPER PREHEAT AREA IN THE RANGE OF 360°. |

| 7 | DOUBLE GLUE MACHINE | 1 | GLUE ROLLER DIAMETER 215MM.EACH INDEPENDENT FREQUENCY MOTOR DRIVE, MANUAL ADJUSTMENT GLUE GAP. |

| 8 | CONVEYOR BRIDGE | 1 | 200MM MAIN BEAM CHANNELS, INDEPENDENT

INVERTER MOTOR DRIVE PULL PAPER FEED, ADSORPTION TENSION.ELECTRIC CORRECTION 。 |

| 9 | DOUBLE FACER | 1 | DRYER SECTION 600MM*12PIECES HOT PLATE, PNEUMATIC LIFT ROLLER, USING

INTENSIVE PRESSURE ROLLER。 |

| 10 | THIN KNIFE SLITTING | 1 | ELECTRIC THIN BLADE,ELECTRIC DETUNING,FIVE

KNIVES EIGHT LINES, BLADE WITH TUNGSTEN ALLOY STEEL MAKING. |

| 11 | NC CUTTER HELICAL KNIVES | 1 | FULL AC SERVO CONTROL, ENERGY STORAGE

BRAKE, HELICAL BLADE STRUCTURE, OILIMMERSED GEARS,10.4-INCH TOUCH SCREEN DISPLAY. |

|

12 |

PAPER SHEET

DELIVERY AND SIDE CONVEYOR |

1 |

ELECTRIC ADJUSTMENT CARDBOARD SIZE, PNEUMATIC CONTROL TRANSVERSE OUTPUT PAPERBOARD. |

| 13 | GLUE STATION SYSTEM | 1 | CUSTOMER-OWNED PIPELINE.GLUE DEVICE

RESPECTIVELY CARRIER POT、MAIN POT、 STORAGE POT、AND SEND GLUE PUMP、BACK GLUE PUMP. |

| 14 | STEAM SYSTEM |