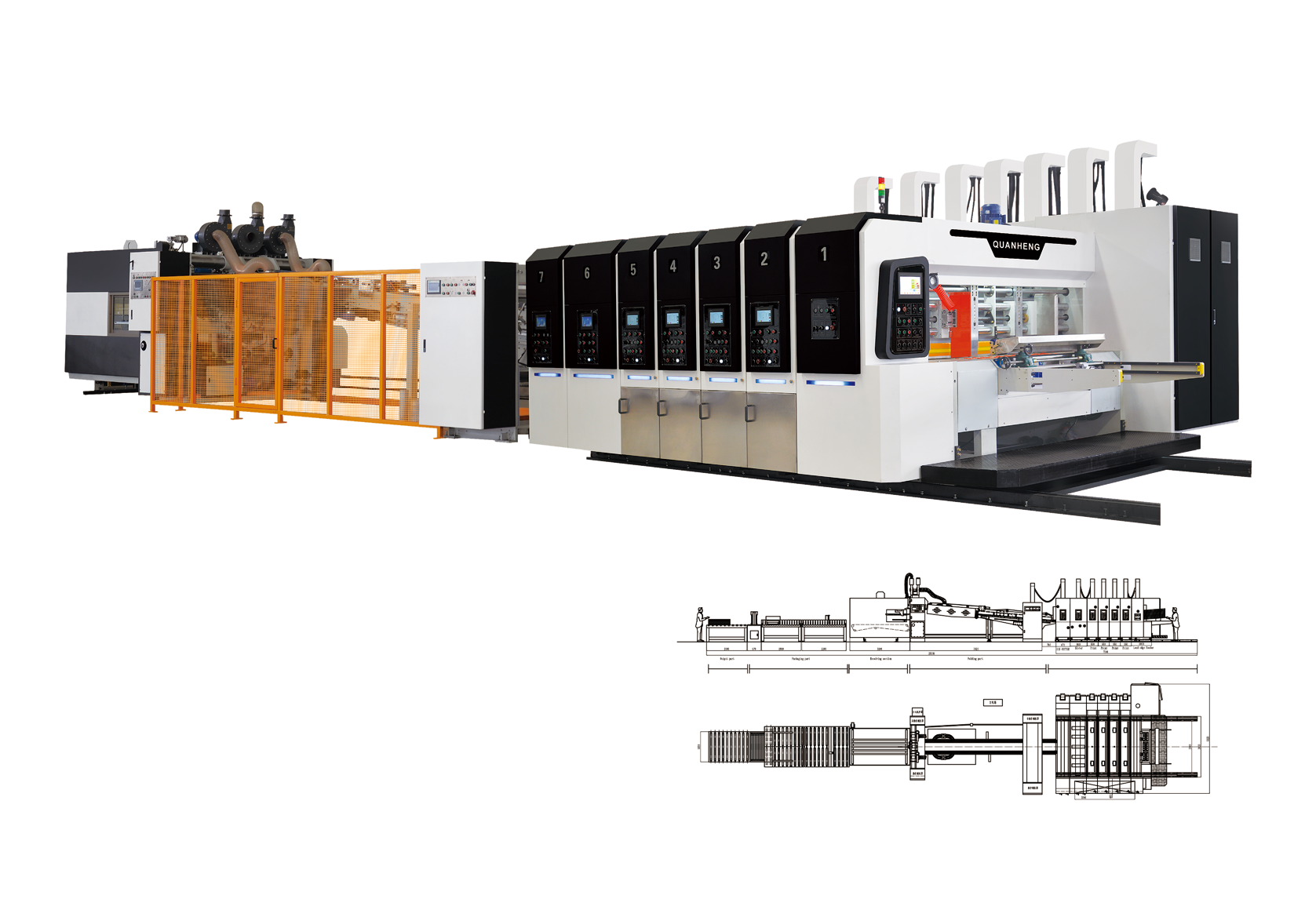

Imported Chain Feeder Printer With Rotary Creaser Slotter (Rs.4) Machine

Chain Feeder MultiColor Flexo Printer for corrugated boxes is used for printing corrugated board at a high speed with best in class quality. With our flexo printer you can target 18,000-30,000 corrugated boards in a day depending on number of SKUs.

Capability and Features

Chain Feeder MultiColor Flexo Printer for corrugated boxes is used for printing corrugated board at a high speed with best in class quality. With our flexo printer you can target 18,000-30,000 corrugated boards in a day depending on number of SKUs.

Key features:

- Helical tooth gears on main drive which adopted 45# steel, treated with gear shaving with high precision facility, closed spray lubrication system, put oil before run the machine, can lower down the noise, decrease the abrasion of gears, and prolong the lifetime of gears

- Adopt the planetary gears phase for the printer slotter driving structure, precise and durable. Phase adjustment adopt Taiwan motor and high quality sensor control, precision is ±0.1mm, exact and reliable.

- All bearings of Chain Feeder Multi color Printing use HRB brand.

- Chain Feeder Multicolor Printing Machine adopts electrical separation, pneumatic locking, pneumatic edition lifting, electric ink distribution, can realize the ink continuous supplying when stop the machine, avoid the ink drying and fading phenomenon when machine stop will affect the printing effect.

- Chain Feeder Multicolor Printing Machine adopt separation positioning by pneumatic, keep the gears engage position not change when machine separated, the dimensions will not change, improving the production efficiency.

- Chain Feeder Multicolor Printing Machine adopt cross-head shoe, for the paper 1mm-11mm thickness, the gears meshing gap keep the same, assure the printing precision and prolong the gears using lifetime.

- Ink guiding system adopt high precision anilox roller with independent motor for ink distribution, high quality diaphragm pump supply ink, can adjust the ink volume randomly, improved the ink supplying more average.

- Chain Feeder Multicolor Printing Machine adopts electrical counter, can control the paper qty exactly, match with warning alarm, can warn workers to keep safe when open or adjust the machine.

- The walking rail material is casting, improving the machine stability.

Additional model available 2200,2800 on request

Color unit available 1-4 color

Additional accessories available (Optional)

- Auto Conveyor Feeder

- Auto Stacker

Technologic parameter

Technologic parameter

| Model | 2400x1400 | 2600x1400 | 2600x1600 |

| Production speed | 60pcs/min | 60pcs/min | 60pcs/min |

| Max printing size | 1400*2200mm | 1400*2400mm | 1600*2400mm |

| Max feeding size | 1200*2400mm | 1400*2600mm | 1600*2600mm |

| Min feeding size | 400*720mm | 450*720 | 450*720 |

| Paperboard thickness | 2-11mm | 2-11mm | 2-11mm |

Related Product

Imported 3 Ply Semi Automatic Flute Laminator

Semi-Automatic flute laminating with Height top feeder suitable for bottom cardboard and cardboard of 350 grams or more, the cardboard and A/B/C/D/E/F and double-layer corrugated cardboard.

Max. Speed: 108m/min

Semi-Automatic flute laminating with Height top feeder suitable for bottom cardboard and cardboard of 350 grams or more, the cardboard and A/B/C/D/E/F and double-layer corrugated cardboard.

Imported Cassette Type Corrugation

The Imported Fingerless Corrugation Machine is designed for efficient and high-quality corrugated board production. It features a negative pressure design for superior bonding and consistent glue application. The machine allows quick roll changes, with durable 48 CrMo alloy steel corrugated rollers and a chrome-treated pressure roller for precise control. An easy-maintenance adhesive roller unit with an adjustable glue system ensures continuous operation. The user-friendly PLC touch control system and integrated pre-regulator optimize paper quality, making this machine a reliable choice for precise and efficient corrugation.

Imported Fully Automatiic Box Stitcher And Gluer Combine Model Machine

The automatic nail-stick box integrated machine is a high-efficiency system for box production, featuring four key sections: Paper Supply, Glue Folding, Stitching and Pressing, and Counting and Stacking. It offers digital speed control, automatic functions, and a production speed of up to 220 sheets per minute. The machine prioritizes energy savings and environmental protection, using advanced motor frequency conversion and Siemens AC contactors for stable operation. It includes a user-friendly touch interface with a Panasonic PLC, ensuring ease of use, maintenance, and future upgrades. Designed for reliability and efficiency, it meets European safety standards.

Imported High Speed Leadedge Printing Slotter And Rotary Die Cutting With Attached Flexo Folder Gluer Machine (FFG)

The Flexo Folder Gluer enhances production efficiency with its user-friendly features and robust design. It includes an intuitive HMI for easy operation, a Shark Anvil Trimming System for continuous performance, and a Lead-Edge Feeder with durable belts for precise sheet control. The flexographic print section offers high-quality prints with a harmonic drive register system and consistent surface speed. The folding section minimizes jams and ensures accurate folds, while the top-loading counter ejector streamlines stacking and counting. Known for its durability, the machine handles diverse product designs with high quality and efficiency.

Imported Hyraulic Shaftless Reel Stand

The Imported Hydraulic Reel Stand offers efficient reel paper handling with motorized controls for lifting, lowering, and positioning. It supports reel papers up to 1500 mm in diameter, with adjustable clamping widths from 600 mm to 2000 mm. The stand features manual tension control via brakes and a 6 kW power system for robust performance. Safety is enhanced by a cycloid motor that prevents overload, ensuring reliable and secure operation in production environments.

Imported Press Type Folder Gluer Machine

The Pressing Type Semi-Automatic Box Gluing Machine combines efficiency and precision with advanced technology and high-quality steel. It processes 40-60 sheets per minute and features an intelligent digital counter for streamlined operation. The stainless steel coating section resists rust and accommodates various adhesives, while optional pasting wheel models cater to different needs. The high-strength conveyor belt system ensures smooth, damage-free transport of cartons, maintaining quality throughout the gluing process.

Imported Thin Blade Electric Adjust Thin Blade Slitter Scorer Machine

Thin Blade Slitter Scorer Machine allows you to adjust slitter and scoring blades with push of a button and pneumatically lock them at the right position. It is our must have offering for commercial corrugation manufacturers who are looking to produce high quality corrugated boxes at a high speed while preserving the edges and flutes.

featured product

Imported 3 Ply Semi Automatic Flute Laminator

Semi-Automatic flute laminating with Height top feeder suitable for bottom cardboard and cardboard of 350 grams or more, the cardboard and A/B/C/D/E/F and double-layer corrugated cardboard.

Max. Speed: 108m/min

Semi-Automatic flute laminating with Height top feeder suitable for bottom cardboard and cardboard of 350 grams or more, the cardboard and A/B/C/D/E/F and double-layer corrugated cardboard.