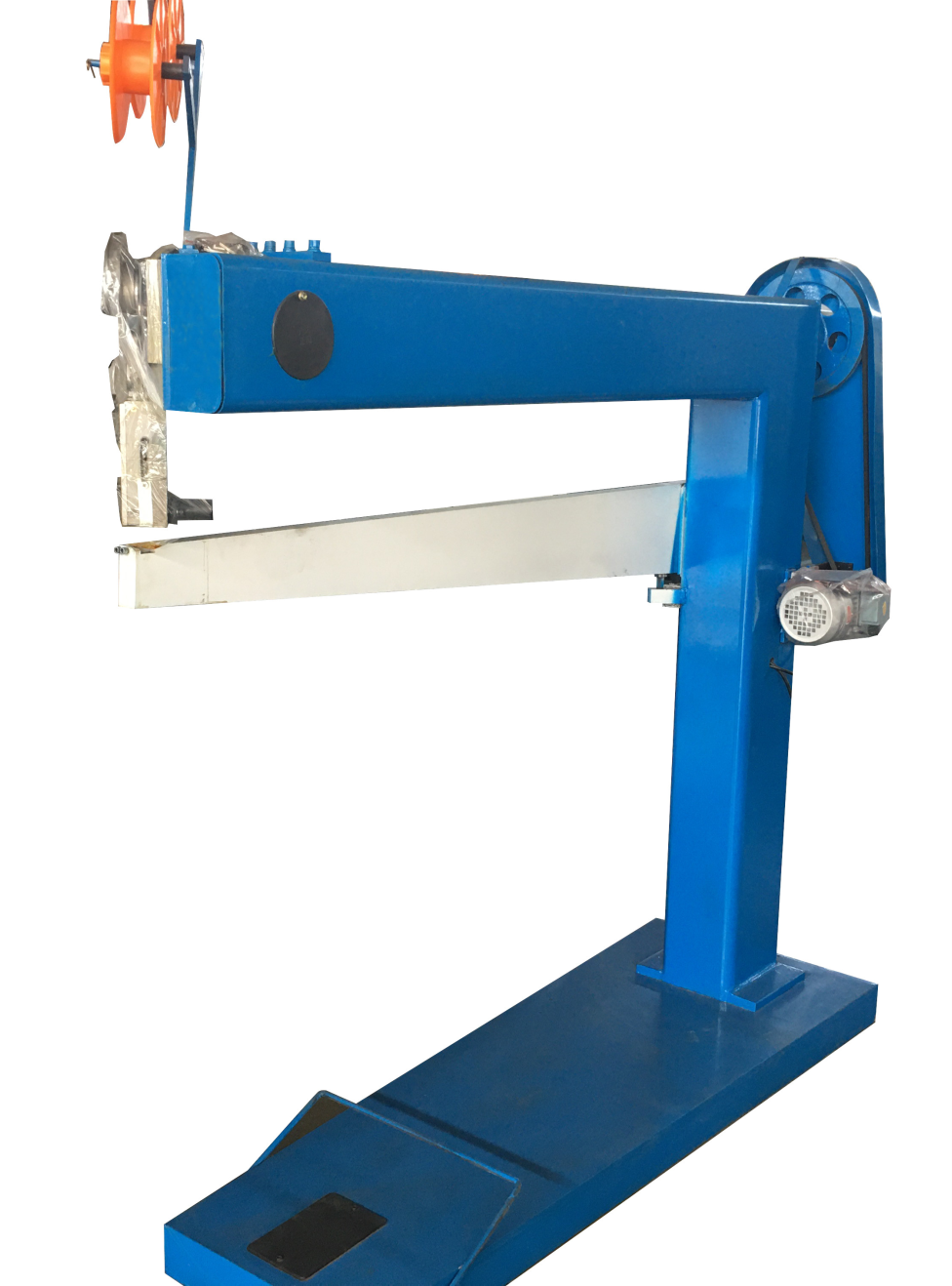

Imported Fully Automatiic Box Stitcher And Gluer Combine Model Machine

The automatic nail-stick box integrated machine is a high-efficiency system for box production, featuring four key sections: Paper Supply, Glue Folding, Stitching and Pressing, and Counting and Stacking. It offers digital speed control, automatic functions, and a production speed of up to 220 sheets per minute. The machine prioritizes energy savings and environmental protection, using advanced motor frequency conversion and Siemens AC contactors for stable operation. It includes a user-friendly touch interface with a Panasonic PLC, ensuring ease of use, maintenance, and future upgrades. Designed for reliability and efficiency, it meets European safety standards.

Capability and Features

The automatic nail-stick box integrated machine is a comprehensive system designed for high efficiency and reliability. It comprises four main parts:

- Paper Supply

- Glue Folding

- Stitching and Pressing Section

- Counting and Stacking

Key features of the machine include digital display speed regulation and microcomputer amplitude modulation, offering simple, fast, reliable, and accurate control. It provides automatic paper supply, automatic glue folding, automatic counting, and automatic stacking output. The machine has an average box production speed of 150 sheets per minute, with a maximum speed of 220 sheets per minute. The nail box speed is 50 units per minute. Our highest priorities are efficiency, energy saving, and environmental protection.

The machine’s electrical components adhere to European standards, ensuring safe and reliable operation. It is designed for ease of use and maintenance, featuring an earlier touch man-machine interface and a Panasonic main control PLC for straightforward operation. The touch interface and main control PLC include reserved program upgrade interfaces, facilitating future equipment upgrades.

The machine uses an active motor frequency conversion speed regulation system with a China Jiale brand frequency converter. This system ensures stable speed, environmental protection, and energy saving, reducing power consumption by about 30%. It also provides full motor protection, with automatic alarms and shutdowns for issues such as high or low voltage, motor overheating, or excessive current, accompanied by corresponding alarm code displays.

Motor control uses Siemens AC contactors equipped with thermal overload relays to protect the motor from heavy loads. All machine parts are connected with air plug-ins, making disassembly and maintenance convenient.

Both the front and back of the machine are equipped with operation buttons, allowing full control from either side. The operation button panel is made of stainless steel, combining beauty with durability. The graphical and textual explanations on the panel make the functions of each button easy to understand.

This machine is designed for high efficiency, energy savings, and environmental protection, aligning with our highest goals in machinery production.