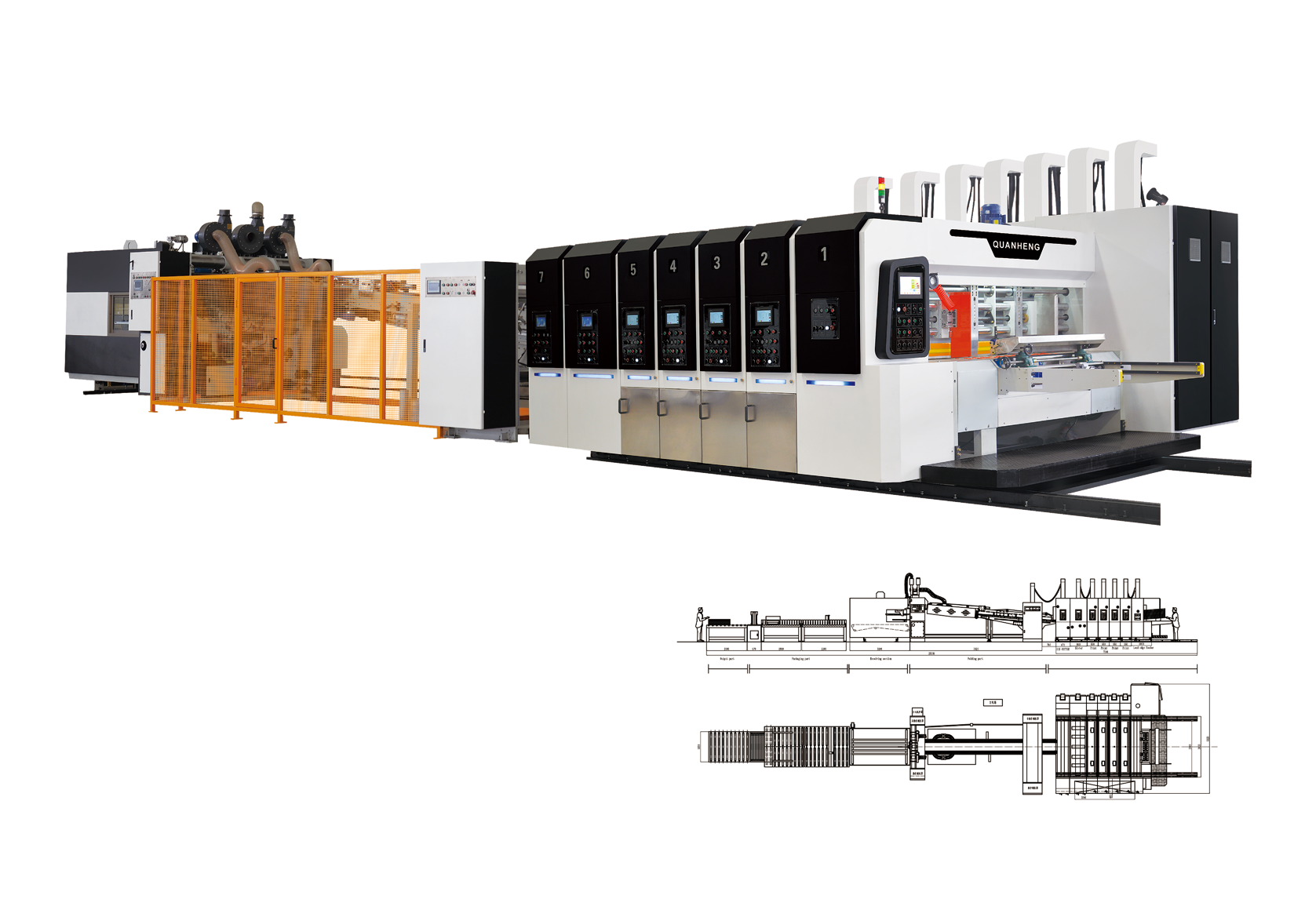

Imported High Speed Leadedge Printing Slotter And Rotary Die Cutting With Attached Flexo Folder Gluer Machine (FFG)

The Flexo Folder Gluer enhances production efficiency with its user-friendly features and robust design. It includes an intuitive HMI for easy operation, a Shark Anvil Trimming System for continuous performance, and a Lead-Edge Feeder with durable belts for precise sheet control. The flexographic print section offers high-quality prints with a harmonic drive register system and consistent surface speed. The folding section minimizes jams and ensures accurate folds, while the top-loading counter ejector streamlines stacking and counting. Known for its durability, the machine handles diverse product designs with high quality and efficiency.

Capability and Features

The Flexo Folder Gluer is designed to streamline production with its robust and user-friendly features, enhancing both operation and maintenance. It incorporates an intuitive Human-Machine Interface (HMI) that simplifies operation and minimizes the learning curve for operators and maintenance personnel. The Shark Anvil Trimming System ensures continuous, even performance by trimming the anvil during operation, reducing downtime.

Equipped with a Lead-Edge Feeder with Extended Feed, the machine utilizes durable urethane belts and a vacuum table to provide precise registration and maximum sheet control, preserving both physical and aesthetic quality. The optional Variable Stroke Feeder further reduces board crushing.

In the Flexographic Print Section, the machine features a harmonic drive register system for precise registration control, managing impression, sheet transfer, and ink metering to achieve high-quality prints. The Vacuum Transfer Print Stations maintain a consistent surface speed, enhancing print registration accuracy and reducing issues with warped boards.

The folding section is designed for smooth, gradual folding with a vacuum system that minimizes fishtail and folder jams. The Forming and Ironing Wheels ensure proper scoring and consistent edges, crucial for producing high-quality boxes with accurate folds.

The machine also includes a top-loading counter ejector for efficient stacking, counting, and ejecting of bundles. Known for its durability and high performance, the Flexo Folder Gluer is capable of handling a wide range of product designs and configurations, maintaining high standards of quality and efficiency throughout its operation.

Related Product

Imported Auto Feeding Thin Blade Slitter Scorer Machine

Imported Chain Feeder Printer With Rotary Die Machine

Imported Chain Feeder Rotary Creaser Slotter (Rs.4) Machine

- Over a decade of R&D to custom design and perfect the product for Indian subcontinent

- 1,000+ installations live in slotter family

- Highly trained and nuanced team of installation technicians

- 24*7 availability of complete range of spares and accessories (only such platform in India).